Who wants to see their home or business blown/floated off its foundation like a ship adrift? No one, excepting Captains Nemo and Ahab. So, let’s go over anchors and how they keep structures grounded.

Historically, bent anchors are common on jobsites, but headed anchors have a notable advantage over hook/J/L anchors. (Pictured below on the left) TIE MAX Edge Bolt anchor with 5,480 lbs allowable tension next to a common 1/2″Ø L-anchor with only 927 lbs capacity (about 6 times less strength):

According to ACI 318 Appendix D 5.3.5, AISC 360-10 equation J3-1, and ACI 318 17.1.3, a cast-in-place headed anchor bolt will tend to form a breakout cone with the concrete. However, L and J bolts have a tendency to slip-pullout of the concrete prematurely. Whereas headed anchors like the proprietary TIE MAX Edge Bolt anchor will reliably achieve the maximum tension capacity of concrete and form a predictable breakout cone.

J/L BENT ANCHOR HEADED ANCHOR

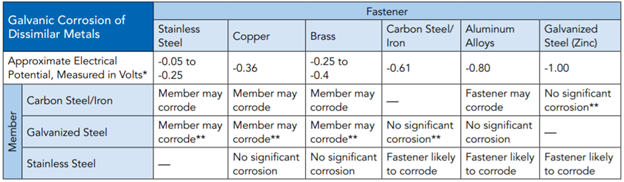

Besides choosing the right anchor, it is also important to understand what finishes should be specified. Corrosion is an important factor when selecting materials. Exposures can range from, interior dry service to an exterior ocean-front location. Typically, interior corrosion is slower and less severe while exterior corrosion is faster and more severe because of environmental factors such as moisture, acid rain, and chemicals. Dissimilar metals can also affect corrosion rates, see AISC table 2-7.

Regardless of which anchor you choose to fit your project; you can find all of these supplies at Fastening Specialists Inc.

Author: Sofia Covelli